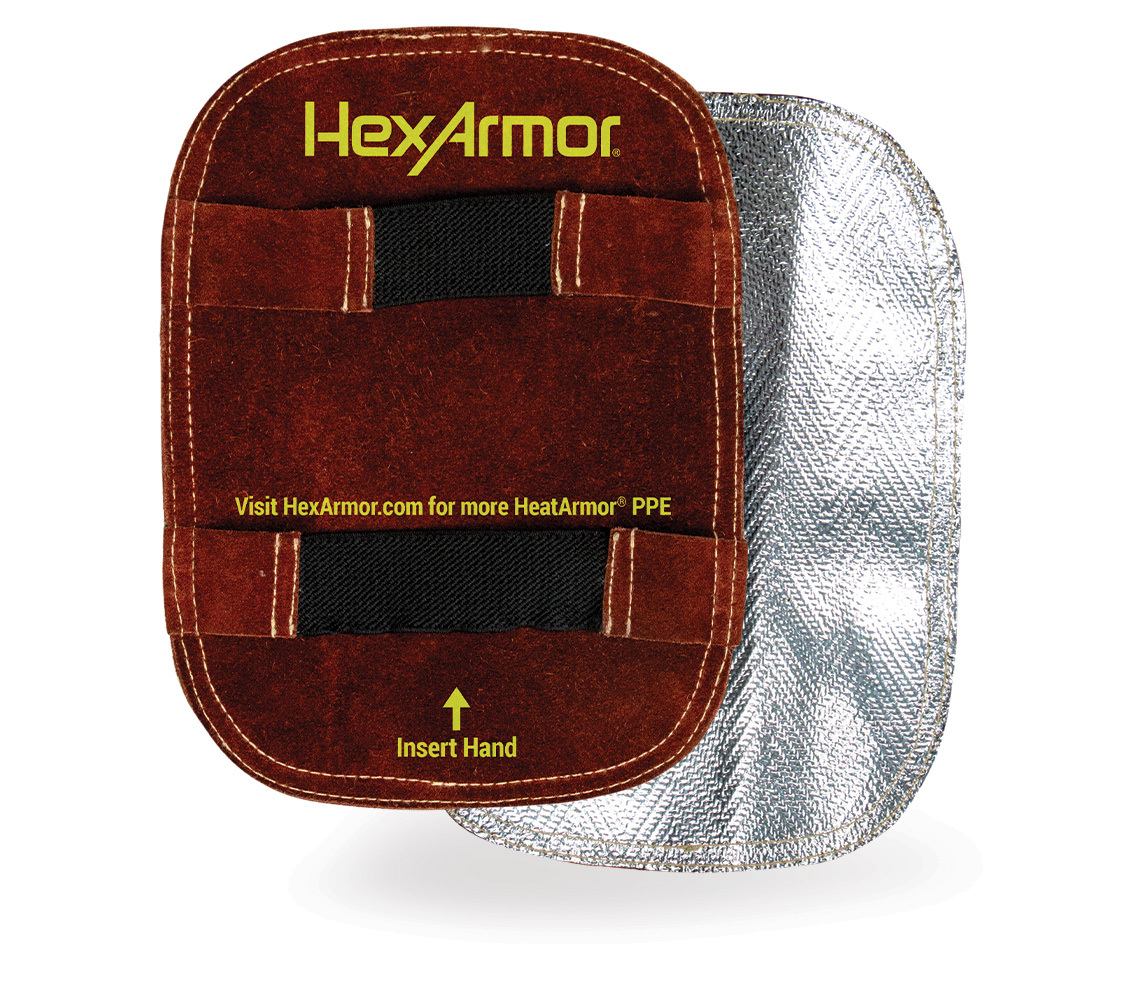

Never sacrifice safety and comfort again

Forget what you know about welding protection. Workers deserve a lineup of welding gear that’s purpose-built for out-of-the-bag comfort, incredible fit, and high-performance safety for any high-heat hazard you can fire at ‘em – and we made it happen with HeatArmor®.